Tasks

● Design a two-stage rocket recovery system for use in a 100 lb hybrid rocket going to 30,000 ft

● Design and build every aspect downstream of the flight computers

● Full ownership of sourcing, manufacturing, integration, and testing of the recovery system

● Work within constraints that rule out black powder-based systems — common in experimental rocketry — due to safety and noise concerns

Actions

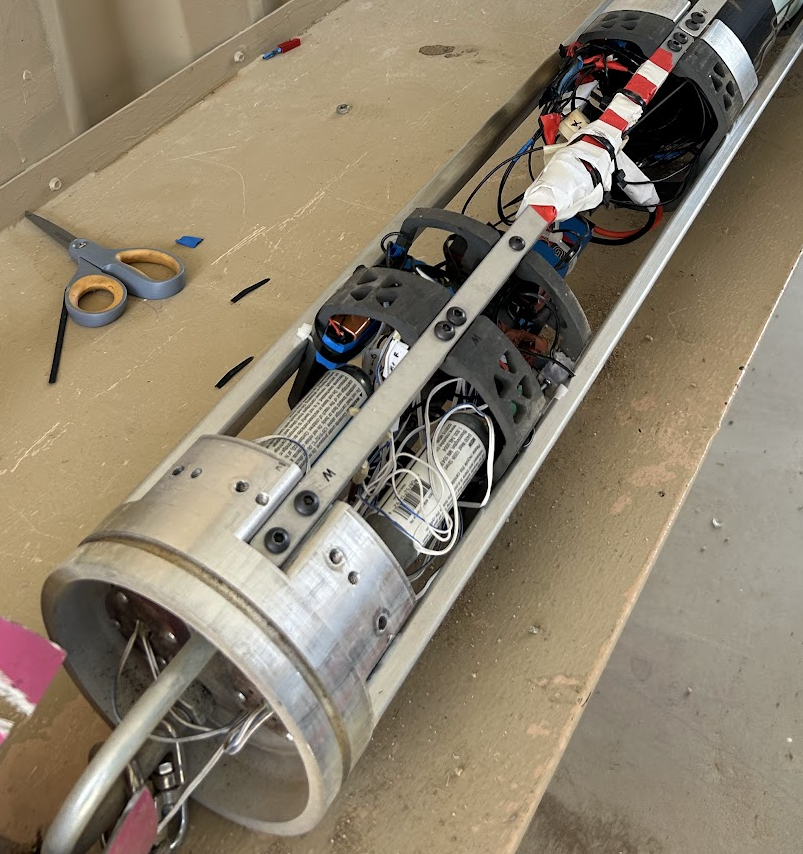

● Designed a CO2-actuated recovery system

● Integrated a mix of custom and commercial parts to ensure complete reliability

● Utilized shear screws, shock cords, swivels, and o-rings to ensure smooth functionality

● Programmed a MATLAB formula to calculate optimal parachute sizes, minimizing shock forces and ground impact speed

● Manufactured a lightweight aluminum recovery bulkhead to withstand over 2000 lbf

● Designed the wiring linking the recovery hardware to the rocket flight computers with maximum redundancy

● Repeatedly tested the integrated recovery system

Results

● System achieved 100% reliability when triggered correctly by flight computers

● This recovery system was used in Columbia's first fully successful launch & recovery in June, 2024

● This recovery system design has continued to be used by Columbia even after I graduated